#OurStories: PROFiBONE: A groundbreaking material for biomedicine is being developed. It can be used to 3D-print bone replacements

Published

The Czech-Icelandic project PROFiBONE presents innovative 3D-printed bone implants designed to meet the specific needs of patients and promote bone healing. This groundbreaking material is being developed by scientists from CEITEC Brno University of Technology in collaboration with the Faculty of Medicine in Plzeň at Charles University and Icelandic partners. They use this material to 3D-print implants that can be precisely customized to fit the patient's size and shape of the bone defect while incorporating necessary bioactive substances.

Almost Like Our Own Bones

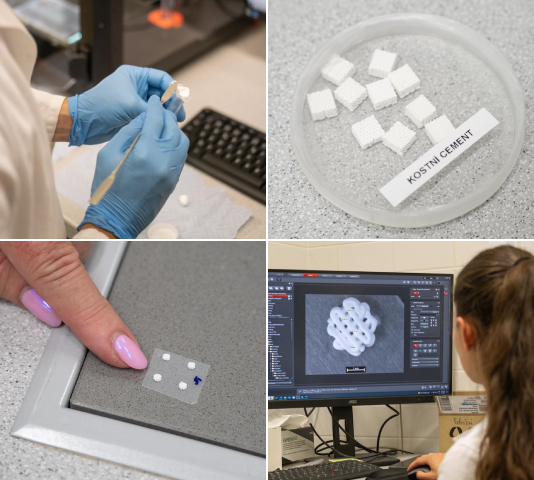

At CEITEC Brno University of Technology, professional bone implants are being developed that can be tailored to both the size and shape of the bone defect and its biological requirements. These implants are 3D-printed using a special bone ink developed as part of the project. This ink consists of a liquid hydrogel component containing a special biodegradable polymer dissolved in water and a powder component of ceramic and cement. Lucy Vojtová, who leads the Advanced Biomaterials group at CEITEC Brno University of Technology and is also the project leader of PROFiBONE, explains that the ceramic component is a special type of calcium-based bone mineral found in our bones.

doc. Ing. Lucy VOJTOVÁ, Ph.D., Research Group Leader (Advanced Biomaterials), CEITEC Brno University of Technology, project leader

"We also enrich these materials with additional substances, such as pro-healing compounds, antibacterial proteins, or growth factors," adds Klára Lysáková, who focuses on hydrogel and cement materials for targeted regenerative medicine as part of her doctoral studies. Her task involves synthesizing these components and preparing a paste for 3D printing. This paste is then used to print the implant at a temperature not exceeding 37°C, and it hardens in strength within a few hours in an incubator. Due to the low temperature, it retains its bioactivity, meaning it doesn't lose the ability to influence living tissue.

Bone implants - 3D printed thanks to a special bone ink

Scaffold for Cells

The key benefit of biodegradable implants in biomedicine is that, unlike previously used materials like metals, they allow the patient's own bone cells to grow into them, ultimately transforming into new bone tissue. As the Biomedical Center in Plzeň explains, the implant essentially acts as a scaffold for new bone cells. During the cell transformation process, the implant retains its mechanical properties, providing sufficient support to the patient until their own bone is fully regenerated. Importantly, the material is eventually absorbed by the body, facilitating the renewal of bone cells without producing any toxic waste. The biodegradable chitosan polymer, part of the implant printing paste, helps with this breakdown. It is produced and supplied by one of the Icelandic partners in the project. Interestingly, chitosan is derived from the exoskeleton of shrimp, making use of a byproduct from the fishing industry. In the future, there are plans to transition to plant-based chitosan obtained from fungi.

Projet team members: Ing. Lucie Vištejnová, Ph.D., Biomedical Center, Faculty of Medicin in Pilsen, Charles University; material chemist Ing. Klára Lysáková from CEITEC Brno University of Technology, Ing. Pavel Janál, project manager from CEITEC Brno University of Technology and MUDr. Anna Malečková, Ph.D. from Institute of Histology and Embryology, Faculty of Medicine in Pilsen, Charles University

A Breakthrough Material for Neurosurgeons (and More)

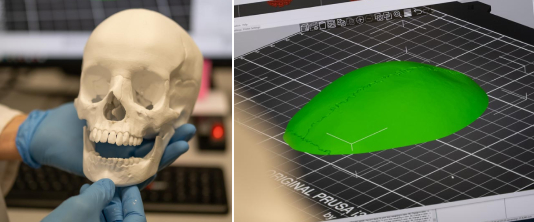

In the future, patients who have undergone craniectomy, a procedure where a portion of the skull must be temporarily removed due to increased intracranial pressure, could benefit from these implants. The reintroduction of the removed bone can be challenging, and in some cases, the original bone may become absorbed upon reinsertion. "When a patient has a part of their skull removed, it's a relatively extensive defect, and any injury could be fatal. The cosmetic effect is also very negative," explains Vladimir Přibáň, the head of the Neurosurgery Department at the Faculty Hospital in Plzeň. Therefore, replacements such as titanium bone plates or polymer implants are used.

Bone implants could be used in surgery where doctors have to remove a portion of the skull an it cannot be put back

However, none of the implants used so far are ideal, and none enable the regeneration of the patient's own bone cells. This deficiency is precisely what the PROFiBONE project aims to address. "In the future, we could create 3D models from this material. The replacement would be precisely tailored to the patient's specifications, matching the shape of their skull," believes neurosurgeon V. Přibáň, envisioning a successful future for the material in professional bone replacements. Collaboration with medical experts directly from the hospital is also a significant benefit of the project. Physicians are enthusiastic about such material and come up with additional ideas for its applications, not only in neurosurgery and orthopedics but also potentially in dentistry.

Advancing the Boundaries of 3D Printing

Thanks to the project, a new advanced 3D printing laboratory has been established in Brno. The special ink used for printing, which needs to be printed at laboratory temperature, cannot be accommodated by traditional 3D printers. Therefore, a special printing head capable of handling this task was developed at CEITEC, and it can be fitted onto commonly available 3D printers. In essence, it is a very similar 3D printing technology to the conventional polymer-based approach, but it uses gel or cement materials instead. Přemysl Menčík, the developer of this printing head, likens it to decorating a cake with icing. The gel-cement material exhibits specific properties during printing, so careful monitoring and control of these properties throughout the implant printing process are necessary, according to the head's author.

A special print head for 3D printers had to be developed to print bone implants. Its author Ing. Přemysl Menčík, Ph.D. from CEITEC Brno University of Technology, a member of the project team, at work

Promising Test Results and Histological Challenges

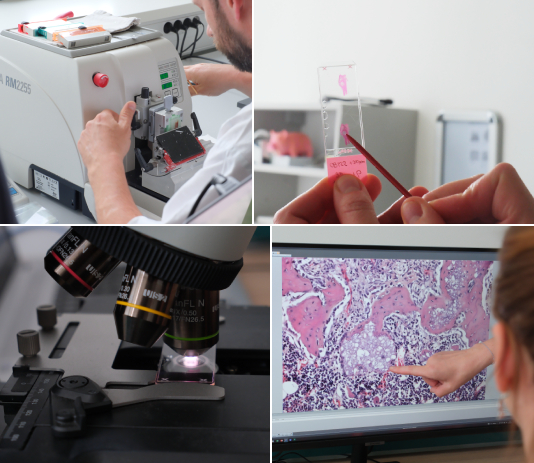

Printed implants are transported from Brno to Plzeň. After successful in vitro testing, where it was demonstrated that the materials are safe for bone cells, scientists moved on to biological testing using animal models. "Since these are implants intended for use in human medicine, we cannot skip this testing phase. It's an integral part of developing implants for the human body," explains Lucie Vištejnová from the Biomedical Center at the Faculty of Medicine in Plzeň, Charles University. During testing, the implant is inserted into the femur or skull bone of a rat. After the implants have fused, bone samples with implants are analyzed. "Our task is to describe how the bone heals and how it responds to the presence of the bone implant. We also evaluate the quality of the newly formed tissue, the presence of inflammation, and the interaction of the bone implant with bone trabeculae," explains histologist Anna Malečková from the medical faculty in Plzeň. So far, everything looks promising.

MUDr. Vladimír Přibáň, Ph.D., Head of the Neurology Clinic kliniky, Fakulty Hospital in Plzeň collaborates on implant testing. Testing implants on animal models cannot be omitted for materials intended for humans.

At the Faculty of Medicine in Plzeň, the project has led to innovations in the histological laboratory's established method of processing bone samples, known as bone histology. In the examined samples, it is necessary to preserve calcium. Instead of the traditional process of decalcifying bone, which can essentially be sliced like other soft tissues, researchers immerse the bone in methyl methacrylate and use special grinders and saws to cut it into thin slices that can be analyzed. "It's a kind of histological hardcore," says L. Vištejnová with amusement.

The decalcified bone sample is cut on a rotary microtome into 5 µm thin slices, placed on a histological slide and stained. Subsequently, the interaction of the implant with the bone tissue is evaluated using a microscope and suitable software.

The Journey to the Operating Room Is Still Long

"When we demonstrate our technology to doctors, they are usually so excited that they want to have it in their hands and use it in the operating room immediately," laughs project manager Pavel Janál. He is the one providing administrative and technical support to scientists so they can fully focus on their work. "Even the fact that, thanks to the project, we are now moving towards a European patent for the material composition of the implant printing paste, in collaboration with colleagues from Iceland and the Plzeň Biocenter, is a tremendous success," he adds. He also hopes that, in the future, the lengthy legislative process can be completed, and the outcomes of the PROFiBONE project will become a common part of medicine.

The PROFiBONE project team at CEITEC Brno University of Technology, led by doc. Ing. Lucy Vojtová, Ph.D.

Thanks to the PROFiBONE project, collaboration between scientists from Brno, Pilsen and Iceland was established.

Info about Researech Programme (also known as "TACR Kappa")

Info about the project PROFiBONE

More about EEA and Norway Grants

Web site of the project PROFiBONE

| Project name: | PROFiBONE |

|---|---|

| Project promoter: | Brno University of Technology (CEITEC - Central European Institut of Technology) |

| Partneři projektu: |

Charles University, Biomedical Center, Faculty of Medicin in Pilsen, Genis hf. (Island) Tæknisetur ehf. | IceTec (Island) |

| Program: | Research |

| Grant: | 33 900 000 CZK |

| Cíl projektu: |

Development of a professional bone implant: low-temperature 3D printing of biofunctionalized ceramic bone implants with tunable mechanical properties |